How to Achieve a Perfect Nail Interlock for Your Projects?

Achieving a perfect nail interlock is essential for any woodworking project. The right interlock ensures durability and strength in your constructions. Getting it just right can be challenging, but understanding the key techniques can lead to great results.

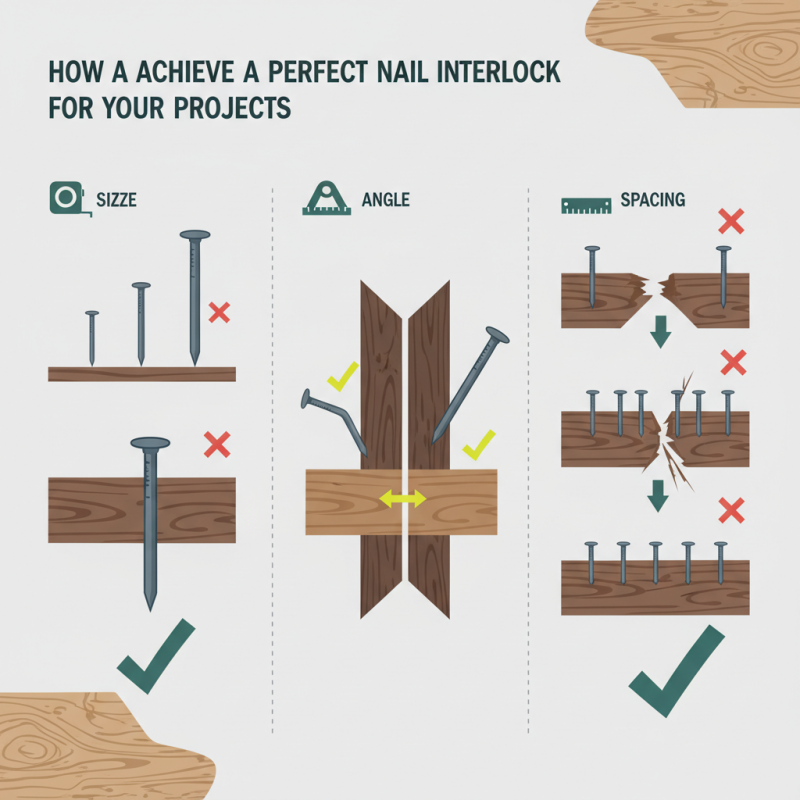

To begin with, use nails that fit snugly. The thickness and length matter significantly. Too short or too thin nails will not provide the strength needed. Additionally, the angle of your nails affects the interlock. A slight misalignment can lead to noticeable flaws, which can ruin the integrity of your work.

Pay attention to the spacing between nails. If spaced too far apart, the joints may not hold up under stress. On the other hand, overcrowding can weaken the wood. It’s easy to overlook these details when in a hurry. Reflecting on past mistakes can lead to better outcomes. A perfect nail interlock is not just about following rules but also about learning from each project.

Understanding Nail Interlock: Definition and Importance

Understanding nail interlock is crucial for any woodworking project. Nail interlock refers to the way nails grip and hold components together. A strong interlock ensures stability in structures like furniture and frames. According to a study by the American Wood Council, proper nail interlock can increase the overall strength of the joint by 45%. This statistic highlights its importance in achieving durable projects.

Achieving a perfect nail interlock requires skill and precision. It's essential to choose the right nail sizes and types for specific materials. Measure twice before making decisions. Aim for a consistent nail spacing of 6 inches apart for optimal reinforcement. This will enhance the interlocking mechanism between pieces, allowing more load-bearing capacity.

Tip: Practice on scrap wood before proceeding with your main project. This helps you refine your technique and avoid costly mistakes. Remember, even skilled woodworkers make errors. Reflecting on what went wrong can lead to better results in future projects. Don’t rush the process; achieving a perfect nail interlock takes time and patience.

How to Achieve a Perfect Nail Interlock for Your Projects?

| Dimension | Description | Importance |

|---|---|---|

| Material | Type of material used for interlocking nails, such as steel, aluminum, or brass. | Affects strength and durability of the joint. |

| Diameter | Size of the nail diameter used in the interlock process. | Critical for load-bearing capacity and stability. |

| Length | Length of the nail used to secure the joint. | Impacts how deep the nail goes into material, affecting tightness. |

| Angle | The angle at which the nails are driven into the joint. | Influences the strength and integrity of the connection. |

| Spacing | Distance between each nail used in the interlocking process. | Affects joint flexibility and strength across the material. |

Essential Tools and Materials for Perfect Nail Interlock

When starting a project that requires a perfect nail interlock, it's crucial to gather the right tools and materials. You’ll need a good hammer, sturdy nails, and a reliable measuring tape. Choosing nails with the right length can significantly impact the overall strength and stability. Ensure you have wood glue as well, as it provides additional bonding.

Consider having a saw handy. Cutting pieces accurately can notice small errors that affect the interlock. Precision requires time and patience. A level can help check that your pieces align correctly. An unsecured piece can lead to an uneven structure. Take breaks to assess your progress. Sometimes stepping back offers clarity.

Another essential element is your workspace. Ensure it’s well-lit and organized. A cluttered space can distract and lead to mistakes. Keep your tools within reach, but not in the way. Test different angles and techniques to find the best fit for your project. Be prepared for trial and error; perfection often takes a few attempts. It’s through reflection on those imperfections that you will refine your technique.

Step-by-Step Guide to Achieving Nail Interlock in Projects

Achieving a perfect nail interlock can seem tricky at first. This process requires attention to detail. Start by selecting the right materials. Use durable nails and sturdy wood that complement each other. The choice impacts the project's overall strength.

Next, ensure accuracy when placing the nails. Measure carefully. A slight miscalculation can lead to gaps. These gaps weaken the structure. So, don’t rush this step. Hammer the nails at the correct angle, ideally 45 degrees. This angle promotes a firmer lock. However, be mindful of overhitting, as it can split the wood.

Lastly, reflect on your technique. Each project is a learning opportunity. If the interlock doesn't seem strong, evaluate your methods. Look for uneven placement or incorrect angles. Adjusting these can significantly improve the final product. Perfecting nail interlock takes practice, but small changes can lead to better results.

Common Mistakes to Avoid for Successful Nail Interlock

Achieving a perfect nail interlock is essential for strong, durable projects. However, many overlook common mistakes that can sabotage their efforts. One prevalent issue is the improper alignment of the nails. According to a recent industry report, misalignment can decrease joint strength by up to 30%. Ensuring that nails are driven in straight and at the correct angle is vital.

Another frequent error involves excessive force when driving nails. Many assume that hammering harder delivers better results, but it can lead to splitting wood. A study highlighted that over 60% of craftsmanship failures stem from this mistake. Instead, focus on consistent, controlled strikes for a better finish.

Finally, neglecting to check for moisture levels in wood can be detrimental. High moisture content can cause shrinkage, leading to gaps and weakened joints. The same report indicated that wood with improper moisture levels could reduce the lifespan of the project by years. Always test wood before starting to ensure your nail interlock remains intact and effective.

Maintenance Tips for Sustaining Nail Interlock Integrity

Achieving a perfect nail interlock requires careful attention. Maintenance is essential for sustaining its integrity. Keeping nails in good condition helps prevent issues during projects.

Regularly check the nails for signs of rust or damage. Replace any faulty nails immediately to ensure stability. Use a light touch when hammering to avoid bending. A bent nail can lead to weak connections. The interlock may not hold properly if nails aren’t aligned.

Consider environmental factors. Moisture can weaken interlocks. Use sealants to protect against the elements. Store materials in a dry place whenever possible. Even minor mistakes can compromise the structure. Be mindful of how you handle each nail; a careless moment may require reworking later on.

Article Source:

CONTACT US

|