How to Use Liquid Sulphur Black for Your Projects?

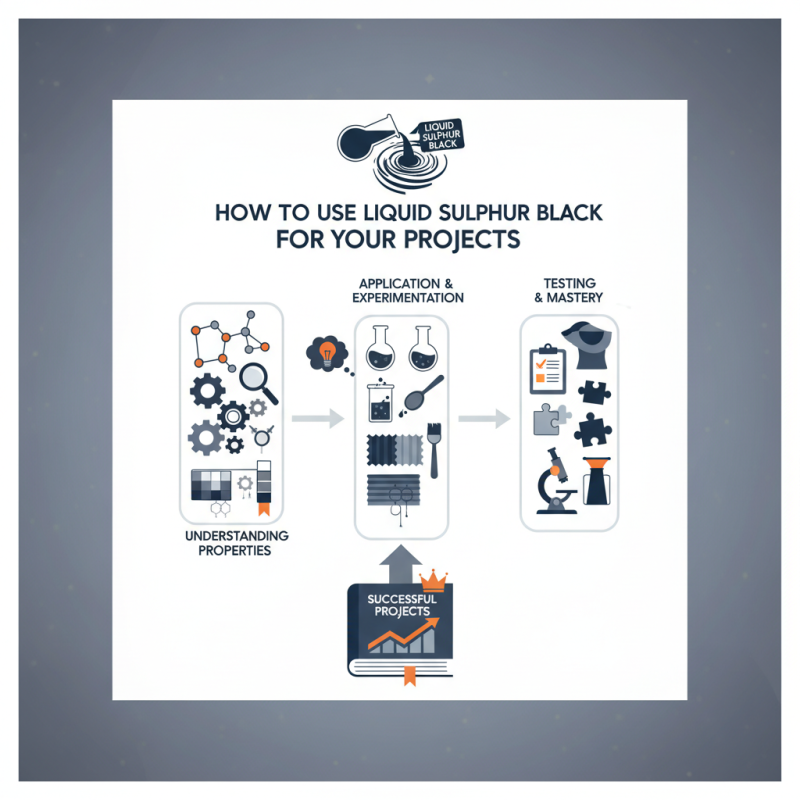

liquid sulphur black has become a vital component in various industrial projects. This pigment offers unique applications, from textiles to coatings. John Smith, an expert in the field of chemical engineering, states, "Understanding the properties of liquid sulphur black is crucial for effective application." His insights highlight the importance of mastering this material before diving into projects.

As you explore the use of liquid sulphur black, consider its versatility. It can enhance both color and durability. However, improper handling may lead to challenges. For instance, achieving the desired shade can be tricky. Users need to experiment with dilution and mixing techniques. Attention to detail is essential for success.

In some cases, projects fail due to lack of preparation. A thorough understanding of liquid sulphur black is necessary. Conduct tests to ensure compatibility with other materials. It’s important to pinpoint the precise application methods. Reflection on these aspects will lead to better outcomes. Through careful practice, you can harness the full potential of liquid sulphur black in your endeavors.

Understanding Liquid Sulphur Black: Properties and Benefits

Liquid Sulphur Black is gaining popularity for a variety of projects. It is a dark pigment known for its versatility and unique properties. This medium is water-soluble, making it easy to mix and apply. Artists appreciate how it interacts with different materials. It delivers rich, deep colors that can enhance any creation.

The benefits extend beyond aesthetics. Liquid Sulphur Black has excellent lightfastness. This means colors will remain vibrant over time. It works well on textiles, wood, and paper. Notably, it should be used in well-ventilated spaces. Safety precautions are essential. Some users experience sensitivity to the components. Testing on a small area first is advisable.

Its application can be tricky. Achieving the desired shade may require experimentation. Sometimes, the color appears different than expected. This unpredictability can be frustrating but also exciting. Artists often find unexpected results lead to creative breakthroughs. Liquid Sulphur Black isn’t just a tool; it invites exploration and growth in the craft.

Liquid Sulphur Black Usage in Various Industries

Preparing for Your Project: Safety Precautions and Materials Needed

Before starting your project with liquid sulphur black, it’s crucial to prioritize safety. Always wear protective gloves and an appropriate mask. This will help prevent skin irritation and respiratory issues. Protective goggles are also necessary to shield your eyes from any splashes. Remember, safety gear is not just an option; it’s essential for a safe working environment.

Gathering the right materials is equally important. You’ll need a clean container for mixing and application tools. Ensure your workspace is well-ventilated to avoid inhalation of fumes. You might find it helpful to have a cloth on hand for any spills—it's better to prepare than clean up later. Take your time to plan the approach and layout. Mistakes are part of any project; reflecting on them afterward can teach valuable lessons. Always have a backup plan for unexpected outcomes.

Step-by-Step Application: How to Use Liquid Sulphur Black Effectively

Liquid Sulphur Black can transform your projects, adding a rich, deep hue. To use it effectively, prepare your workspace. Wear gloves and goggles for safety. It’s essential to have adequate ventilation. Start by mixing the liquid with water or other mediums as instructed. A smaller amount often creates a looser, lighter shade. Adjusting the concentration allows for versatility.

Before applying, test the mixture on a scrap piece. Sometimes, the color may turn out darker than expected. This trial can save time and resources. If the outcome isn’t perfect, reassess your mix and technique. It’s a learning process.

Tips: Clean your brushes thoroughly after use. Dried sulphur can ruin them. Additionally, consider the drying time. Impatience may lead to smudges. Monitor your environment for humidity and temperature. These factors can impact the drying speed. Don’t rush; sometimes, you need to step back and wait.

Cleanup and Disposal: Best Practices After Using Liquid Sulphur Black

Proper cleanup and disposal after using liquid sulphur black is crucial for environmental health and safety. This pigment is commonly used in various industries, including textiles and coatings. According to a recent report from the Environmental Protection Agency, improper disposal of chemical waste can contaminate local water sources. Ensure you follow best practices to mitigate this risk.

After completing your project, collect any leftover liquid sulphur black. Store it in a sealed, labeled container. Never pour it down the drain or throw it in regular trash. Some reports indicate that around 50% of industrial waste water contains harmful substances that lead to long-lasting environmental damage. It’s best to consult local regulations for specific disposal methods.

For cleaning tools, use solvent-based cleaners as liquid sulphur black can harden quickly. However, some cleaners might not be entirely effective. Sometimes, residue remains on brushes or rollers. After cleaning, ensure your workspace is free from any spills. Remember, practicing proper disposal and cleanup protects not just you but also the environment for future generations.

Common Mistakes to Avoid When Using Liquid Sulphur Black

Using Liquid Sulphur Black can enhance various projects, but common mistakes can lead to poor results. Many users overlook the importance of surface preparation. This step is crucial. If the surface is not clean, the liquid won’t adhere properly. Always clean surfaces thoroughly before application.

Another mistake is ignoring drying times. Rushing this process can lead to uneven color and texture. Make sure to allow each layer to dry completely. This may mean waiting longer than expected. It's important to have patience.

Tips: Always apply in thin layers. It helps achieve a uniform finish. Don't forget to wear safety gear, even if it feels unnecessary. Small oversights can lead to big problems. If your project doesn’t turn out as expected, don’t be discouraged. Reflect on what went wrong and adjust your technique for future use.

Article Source:

CONTACT US

|